The Next Generation of HSD-Powered PWHT Solutions

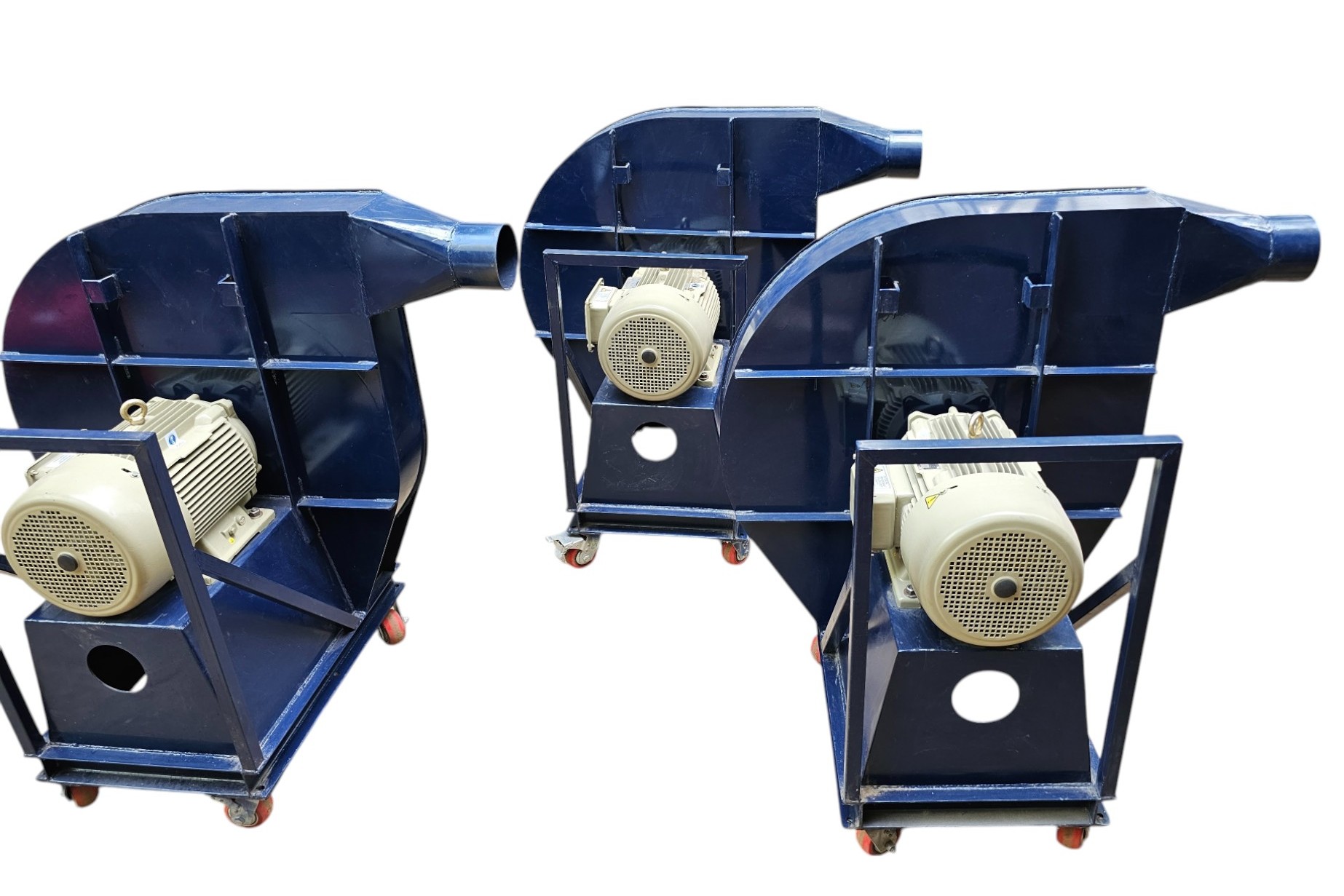

PWHTTech India introduces the PWHT FireWave System, an innovative High-Speed Diesel (HSD)-powered heat treatment solution designed to streamline and enhance the Post Weld Heat Treatment (PWHT) process. Engineered for pressure vessels, storage tanks, offshore structures, and heavy industrial fabrications, the FireWave System provides consistent, high-efficiency heating with optimized fuel consumption, reducing operational costs while meeting stringent industrial standards.

PWHT processes often run for 30 to 40 hours, requiring reliable, controlled, and uniform heat distribution. The FireWave System overcomes industry challenges related to power consumption, heat loss, and environmental constraints by using high-performance HSD burners, advanced thermal insulation, and intelligent temperature control systems.

The system supports two primary PWHT methods, making it versatile and adaptable for various industrial applications:

1️⃣ Internal Firing Method – Heat is applied through nozzles, manholes, or designed openings, with external insulation reducing heat loss.

2️⃣ Furnace-Based Method – A temporary or permanent furnace is enclosed with high-temperature ceramic insulation, allowing uniform heating from external HSD burners.

Both methods are widely used across global industries and approved under international standards such as ASME, API, and other industrial regulations, ensuring compliance, safety, and efficiency.

Key Features & Advantages of the PWHT FireWave System

1. HSD-Powered High-Efficiency Heating

✅ Stable and Reliable – High-Speed Diesel (HSD) burners provide continuous, consistent heating, ensuring optimal metallurgical transformation.

✅ Energy Efficient – Consumes less fuel compared to traditional methods while maintaining required heat intensity.

✅ No Gas Dependency – Reduces risks and costs associated with gas storage, transport, and safety compliance.

✅ Fast Heating & Recovery – Shorter heat-up and recovery times, ensuring efficient PWHT cycles.

2. Internal Firing Method for In-Component Heating

✅ Best suited for pressure vessels, storage tanks, and spiral tanks.

✅ Heat is introduced through manholes, nozzles, or controlled inlets, ensuring direct heat penetration.

✅ Minimizes heat loss with advanced external insulation techniques.

3. Furnace-Based Method for Large-Scale Applications

✅ Can be deployed as a temporary or permanent furnace, based on project requirements.

✅ Fully enclosed with high-temperature ceramic insulation, preventing heat leakage.

✅ Ideal for offshore structures, shipbuilding, heavy equipment fabrication, and power plants.

✅ External HSD-fired burners ensure uniform, controlled heating for large and complex structures.

4. Industry-Approved & Globally Recognized PWHT System

✅ Fully compliant with ASME, API, AWS, and other international PWHT standards.

✅ Suitable for oil & gas, shipbuilding, power generation, aerospace, and heavy engineering industries.

✅ Delivers precise heat control, preventing material warping, cracking, or welding failures.

5. Smart Control & Automation for Enhanced Efficiency

✅ Equipped with digital PID-based controllers, ensuring precise temperature regulation.

✅ Programmable heat cycles, allowing customized preheat, soak, and cooling rates.

✅ Remote monitoring & control (optional), enhancing operational safety and convenience.

6. Complete Turnkey Solutions & Global Support

✅ PWHTTech India offers end-to-end solutions, from equipment supply to installation and operation.

✅ On-site training and technical assistance for seamless equipment integration.

✅ 24/7 global service support for troubleshooting, maintenance, and process optimization.

Ideal Applications of the PWHT FireWave System

The PWHT FireWave System is designed to cater to industries that require precision heat treatment for heavy-duty welded components, including:

Oil & Gas Refineries – PWHT for pipelines, vessels, and storage tanks.

Shipbuilding & Marine Engineering – Used for hull and structural weld stress relief.

Heavy Engineering & Offshore Fabrication – Ideal for rig structures, bridges, and industrial frameworks.

Power Plants & Energy Sector – Applied in boiler, turbine, and heat exchanger PWHT.

Aerospace & Defense Manufacturing – Ensures material integrity and longevity.

Nuclear & Thermal Power Projects – Used in reactor components and steam piping heat treatment.

Technical Specifications of the PWHT FireWave System

Feature Specification

PWHT Method : Internal Firing & Furnace-Based

Equipment Name: PWHT FireWave System

Fuel Type :High-Speed Diesel (HSD)

Heat Source :HSD Burners

Insulation Type : High-Temperature Ceramic Fiber

Temperature Range: 600°C – 1,100°C (Customizable)

Process Duration: Adjustable (Typically 30-40 Hours)

Standard Compliance :ASME, API, AWS, and Global PWHT Standards

Setup Options :Temporary or Permanent Furnace Configuration

Control System :Digital PID-Based Temperature Controllers

Automation :Programmable Heat Cycles & Optional Remote Monitoring

Service Support Global Installation, Maintenance & Training

Why Choose PWHTTech India?

PWHTTech India has been a trusted global provider of advanced PWHT solutions for over a decade, supplying high-quality, innovative, and industry-compliant equipment to leading industrial sectors worldwide.

Key Advantages of the PWHT FireWave System:

✔ HSD-powered burners ensure efficient, safe, and cost-effective heating.

✔ Dual PWHT methods (Internal Firing & Furnace-Based) for maximum flexibility.

✔ High-performance ceramic insulation minimizes heat loss and enhances energy efficiency.

✔ ASME-compliant technology, ensuring international quality and safety standards.

✔ Comprehensive service support, including on-site setup, training, and maintenance.

✔ Global supply & expertise, ensuring your PWHT needs are met anywhere in the world.

Enhance your PWHT process with the industry-leading FireWave System from PWHT Tech India!